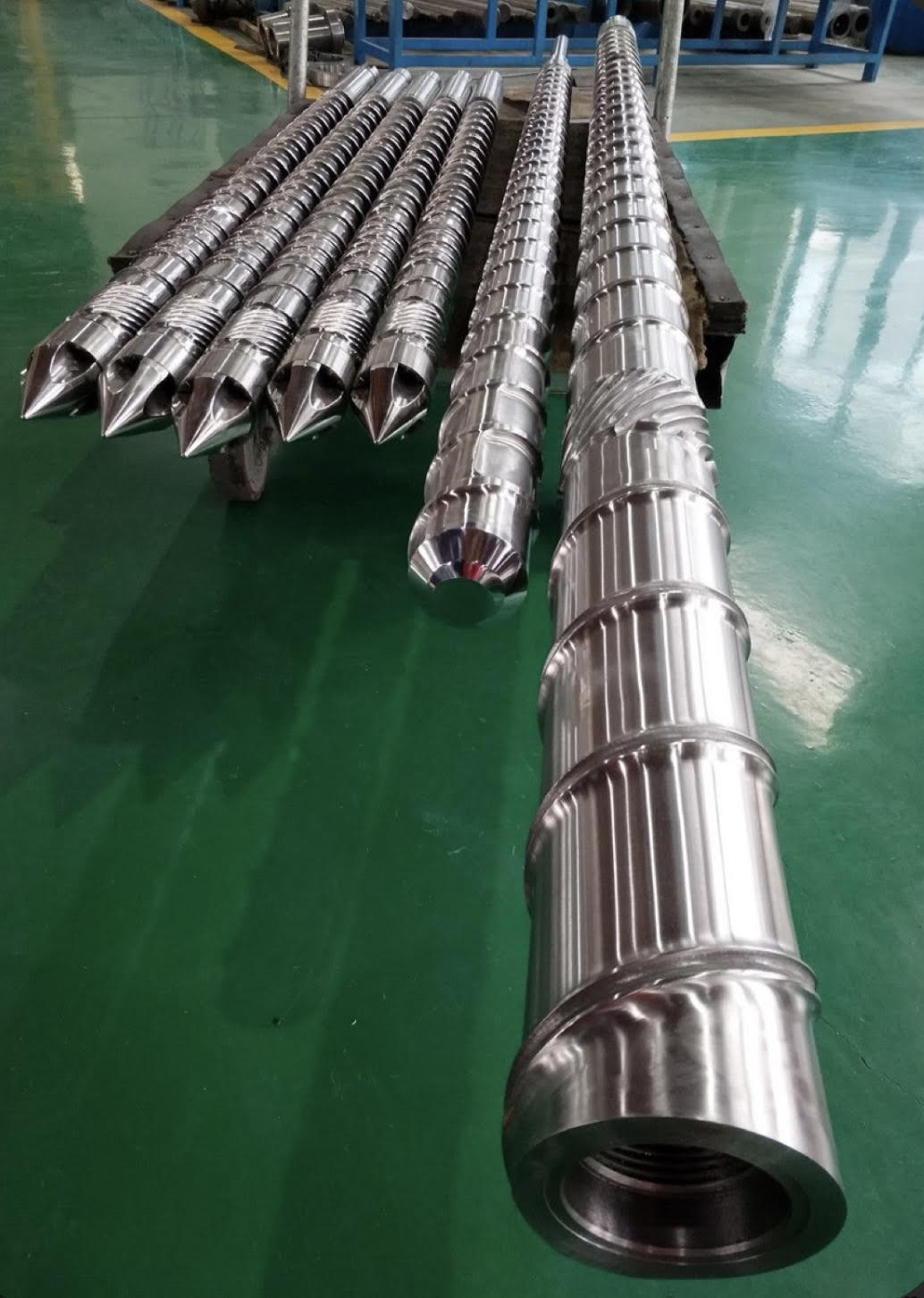

Screw and barrel repair

Our expertise encompasses the repair and refurbishment of a wide range of extrusion components, including screws, barrels, feed throats, injection molding screws, and more.

Screw and barrel repair

At GER, we have developed a unique approach to restoring equipment to its original specifications, ensuring extended longevity and performance. Even in cases where equipment is chipped, broken, or cracked from previous grinding, we possess the capability to refurbish it to manufacturer standards.

Our repair and rebuild services cover a comprehensive range of tasks, including flight repairs, root and radius repairs, and full-length coatings on extrusion and injection screws. Flight repairs are meticulously executed using a multi-step welding process involving plasma transferred arc welding, supported by a rigorous quality control system. Root and radius repairs are undertaken with compatible base metals or hard surfacing to provide added protection against future damage. Additionally, full-length coatings offer enhanced durability, particularly for extruders processing reinforced resins.

We are also adept at repairing and rebuilding pelletizers, including strand, underwater, and water ring pelletizers, ensuring optimal efficiency upon completion. Whether it involves a simple knife change or a complete rebuild of the entire unit and drying system, our knowledgeable staff, machining capabilities, and comprehensive parts inventory enable us to tackle any job with precision and expertise.

At GER, we believe no equipment is beyond salvaging. Our advanced grinding and polishing equipment, including center-less grinding capabilities and various welding techniques, allow us to efficiently restore equipment to peak condition. Moreover, we stand behind our workmanship with a guarantee of (36) months from the time of installation.

Get in touch

For expert extrusion component repair and refurbishment services, contact us today to discuss your needs.